Book a Consultation

Classifications and Credentials:

What a Professional Railroad Track Inspection Should Include

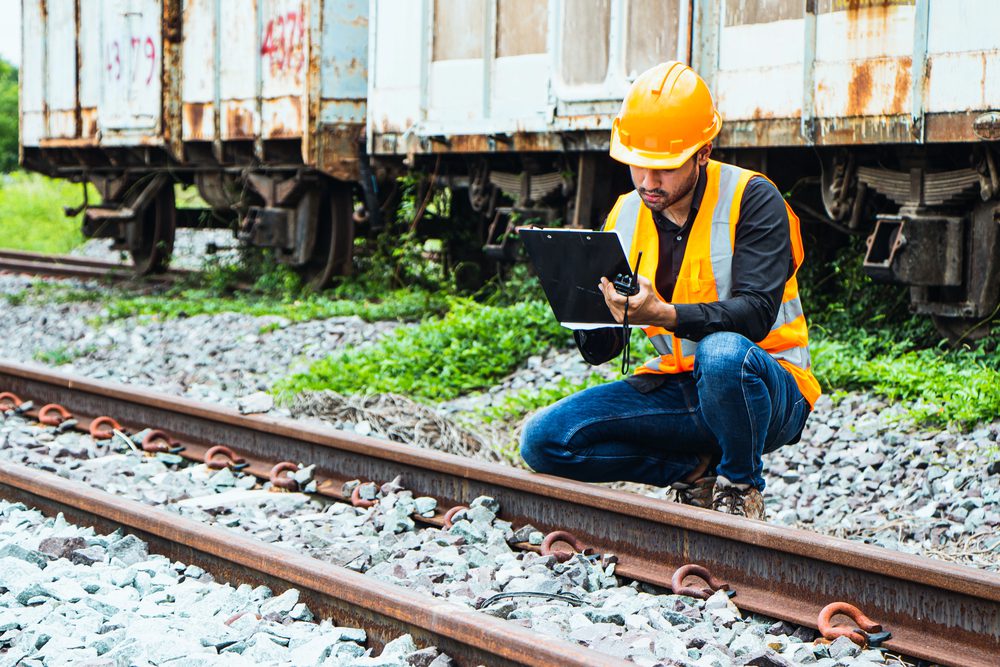

Railroad track is an asset you can’t afford to guess about. If you operate a short line railroad, manage an industrial spur, or oversee a commercial rail facility, the condition of your track directly impacts safety, regulatory compliance, operating costs, and service reliability. That’s why a professional railroad track inspection isn’t just a formality; it’s a tool for protecting your infrastructure and your business.

Yet not all inspections are created equal. A truly professional railroad track inspection goes far beyond a quick visual check. It follows defined standards, aligns with FRA track inspection requirements, and provides actionable data you can use for maintenance planning and budgeting.

Understanding what a proper inspection should include helps you evaluate inspection providers, prepare for regulatory reviews, and make informed decisions about track maintenance and capital improvements.

Why Railroad Track Inspections Matter

At its core, a railroad track inspection serves three essential purposes:

- Safety: Identifying defects that could lead to derailments or failures

- Compliance: Meeting FRA track inspection requirements and documentation standards

- Asset management: Providing the data needed to prioritize maintenance and control long-term costs

Deferred or incomplete inspections often lead to emergency repairs, unplanned outages, and increased liability exposure. Proactive inspections, on the other hand, allow owners to address issues early, when fixes are less disruptive and far more cost-effective.

FRA Track Inspection Requirements: The Baseline Standard

The Federal Railroad Administration establishes minimum requirements for track inspections based on track class, usage, and operating conditions. These requirements dictate:

- Inspection frequency (weekly, bi-weekly, or more frequent, depending on track class)

- Who is qualified to perform inspections

- What conditions must be evaluated and documented

While FRA track inspection requirements define the baseline, a professional inspection program typically goes further. The goal isn’t just to “pass” an inspection, it’s to understand the true condition of the track and plan intelligently for maintenance and rehabilitation.

Elements of a Professional Railroad Track Inspection

1. Rail Condition and Wear Evaluation

A professional railroad track inspection begins with a detailed assessment of the rail itself. This includes:

- Head wear, side wear, and vertical wear

- Cracks, fractures, or surface defects

- Joint bar condition and bolt integrity

- Evidence of rolling contact fatigue

Identifying rail defects early helps prevent sudden failures and supports long-term rail replacement planning, rather than relying on reactive repairs.

2. Crossties and Fastening Systems

Ties and fasteners play a major role in maintaining gauge, alignment, and overall track stability. A thorough inspection evaluates:

- Tie condition (wood, concrete, or composite)

- Percentage of effective ties per segment

- Plate cutting, spike kill, and loose fasteners

- Missing or damaged anchors and clips

Tie condition is a factor in FRA track class compliance and one of the most common drivers of speed restrictions if left unaddressed.

3. Ballast and Subgrade Condition

Ballast performance directly affects drainage, load distribution, and track geometry. A professional railroad track inspection includes:

- Ballast depth and shoulder condition

- Fouling, mud pumping, or contamination

- Drainage performance and standing water issues

- Evidence of subgrade instability

Poor ballast and drainage are often the root cause of recurring geometry problems, making this assessment important for long-term maintenance strategies.

4. Track Geometry and Alignment

Track geometry defects are among the most common causes of FRA violations. Professional inspections assess:

- Gauge variation

- Cross-level and superelevation

- Alignment and surface deviations

- Warp and curvature issues

These measurements help determine if the track meets FRA track inspection requirements for its designated class and operating speed.

5. Turnouts, Crossings, and Special Trackwork

Turnouts and crossings experience higher stress and failure rates than tangent track. A complete inspection includes:

- Switch points and stock rails

- Frogs, guard rails, and flangeways

- Rods, throw mechanisms, and locking devices

- Roadway crossing panels and approaches

Because failures in these areas can cause immediate operational disruptions, they require careful, documented evaluation.

6. Vegetation and Right-of-Way Conditions

Vegetation management is often overlooked, yet it remains a compliance and safety concern. Professional inspections review:

- Vegetation obstructing visibility or drainage

- Growth interfering with track structure or signals

- Tree encroachment risks during storms

Unchecked vegetation can accelerate track degradation and create compliance issues during FRA reviews.

7. Documentation and Reporting

An inspection is only as valuable as the information it produces. A professional railroad track inspection provides:

- Clear, organized inspection reports

- Location-specific defect identification

- Photographic documentation when appropriate

- Prioritized recommendations for maintenance and repair

Proper documentation supports FRA compliance, informs maintenance budgeting, and protects owners during audits or incident investigations.

Beyond Compliance: Using Inspection Data Strategically

Meeting FRA track inspection requirements is essential, but the real value of a professional inspection lies in how the data is used. High-quality inspection results support:

- Preventive maintenance planning instead of emergency repairs

- Accurate budget programming for tie, rail, ballast, and surfacing work

- Capital improvement planning for rehabilitation or reconstruction projects

- Reduced outages and operational disruptions

When inspection findings are integrated with maintenance and construction planning, track owners gain control over costs, schedules, and risk.

Choosing the Right Inspection Partner

Not all inspection services deliver the same level of value. When selecting a provider, railroad owners should look for:

- Proven experience with short line, industrial, and commercial railroads

- Knowledge of FRA track inspection requirements

- Access to modern Maintenance of Way equipment and tools

- The ability to translate inspection data into actionable maintenance plans

An experienced partner doesn’t just identify problems; they help you solve them efficiently.

Track Tech’s Approach to Professional Railroad Track Inspection

A professional railroad track inspection is far more than a regulatory checkbox. When done correctly, it provides a clear picture of track condition, ensures compliance with FRA track inspection requirements, and gives owners the insight needed to plan maintenance, manage budgets, and avoid costly surprises.

By understanding what a complete inspection should include, railroad owners are better equipped to protect their infrastructure, improve safety, and extend the life of their track assets.

Learn more about our railroad track inspection and maintenance services.